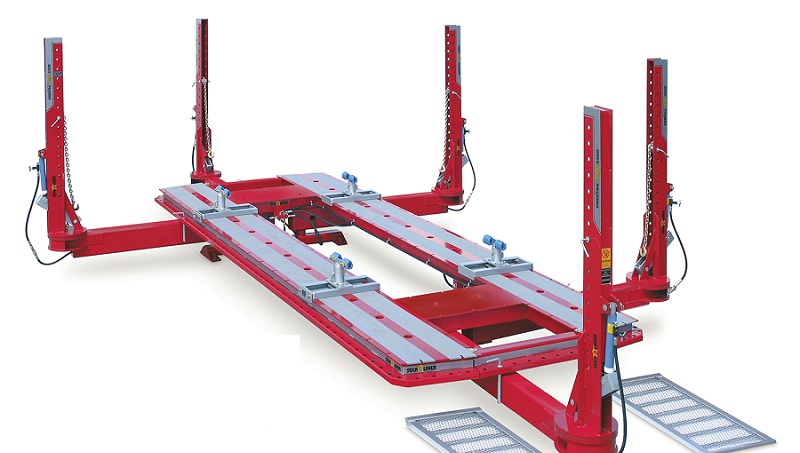

CR100 – Welding & Cutting

Students will learn welding techniques using MIG and arc welders and how to safely use oxy-acetylene. Students will learn how to identify the proper weld to use in different situations and how to join the different types of metal. Students will also learn the various cutting techniques. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the welding methods common to the collision repair industry will be assigned and is an integral component of this course.

Welding & Cutting is a student favorite. The course applies to a plethora of occupations both in and out of the automotive fields. It is a mandatory skill in the collision industry, as it is needed to repair and replace structural and non-structural components alike. However, it is also a skill utilized outside of the industry as well; everything from manufacturing to shipbuilding

Dennis Gregory, ASE Master Collision Technician