TD210 Diesel Engine Accessories

This lecture/laboratory course focuses on the diesel engine accessories that aid in the enhancement of engine power, performance and lower diesel emissions. Topics discussed include air induction and exhaust systems, turbochargers, superchargers and engine braking systems. A thorough discussion of diesel engine system preventive maintenance and inspection practices are also included. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of a diesel engine’s air induction system, exhaust system, turbocharger, supercharger

EG102 – Technical Communications

This course continues the advancement of reading and writing in the context of the technical environment in which most students will work after achieving their degrees. Students will read and write technical reports, memos, personnel commentary and other documents of value in automotive work. Students will continue to advance their skills in research-based writing and will be required to submit a research-based report.

TD204 – Advanced Heavy Duty Undercarriage

This course combines lecture and laboratory hands-on activities, focusing on the theory of operation, construction, diagnosis and repair of heavy duty clutch assemblies, manual transmissions, drive lines and final drive assemblies. The laboratory component of the course includes the practical aspects of maintenance, troubleshooting and overhaul procedures used in heavy duty power train components. Chassis preventive maintenance and inspection (PMI) will be covered in detail. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project

TD202 – Diesel Fuel Systems

This lecture/laboratory course begins with the discussion diesel engine fuel composition from crude oil to the distillation and compounding of fuels in accordance with American Petroleum Institute’s standards. Fuel delivery systems are discussed in detail including fuel tanks, pumps, fuel lines and filtration devices. The various mechanical and electronic fuel injection systems used on diesel engines are discussed in great detail with an emphasis engine performance and diesel emission requirements. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF).

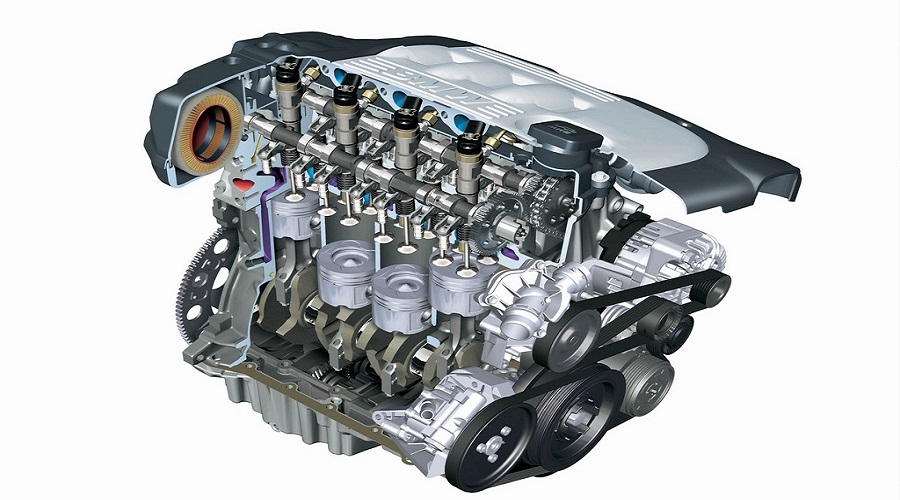

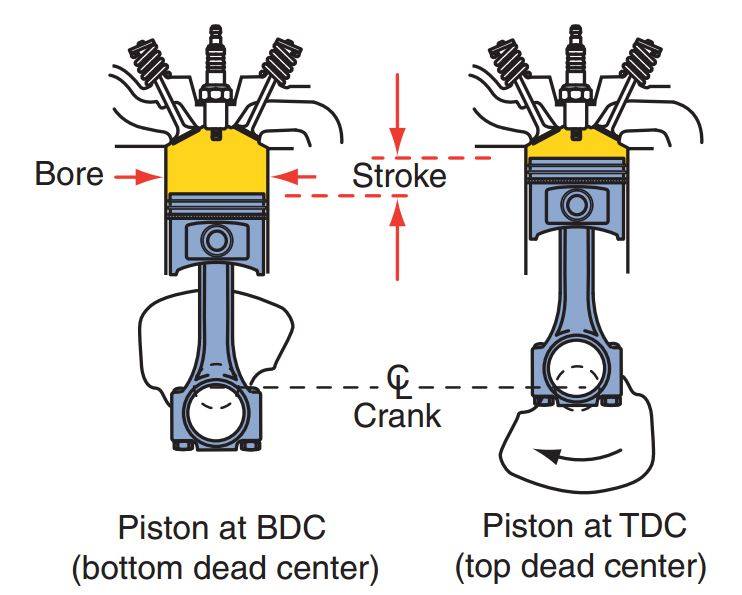

TD102 – Diesel Engines

This course combines lecture and laboratory hands-on activities, focusing on the fundamentals of diesel engine repair and rebuilding. Students will learn how to disassemble, diagnose, measure and repair cylinder heads, engine blocks, pistons and connecting rods, crankshafts and valve trains on Caterpillar and Mack diesel engines. Emphasis will be placed on the proper use of precision measuring tools such as outside micrometers and cylinder bore gauges. Students will learn to perform a complete diesel engine overhaul. The laboratory component of the course includes various activities that follow the guidelines of

TD101 – Heavy Duty Braking Systems

This course combines lecture and laboratory hands-on activities, focusing on the fundamental operation and servicing of medium and heavy duty vehicle braking systems. Essential topics include a discussion of drum brakes, disc brakes, brake components, system operation, hydraulic and air braking systems. Medium and heavy duty vehicle anti-lock braking systems and traction/stability control systems will be taught utilizing training system simulators. Training simulators will also be used to aid the student in understanding the diagnostic procedures needed to properly service tractor and trailer air brake systems. The laboratory component of

TD100 – Heavy Duty Steering & Suspension

This course combines lecture and laboratory hands-on activities, focusing on the fundamental operation of medium and heavy duty vehicle steering and suspension systems. Topics discussed include safety practices, tires, wheels, wheel bearings, steering systems and suspension systems. Students will learn the proper diagnostic and repair procedures for the various steering and suspension systems discussed in this course. The student will also learn the principles and practices of wheel alignment on heavy duty vehicles. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians

SS100 – The Automobile and Society

Over the course of its history the automobile rapidly developed from an expensive toy for the rich into the standard for passenger transport in most of the world. In this course students will learn about the effect of the automobile on society, especially during the 20th century. Topics discussed include advantages of the increase in mobility and convenience afforded by the automobile, the effect on pollution and the growth of the suburbs caused by the automobile. A library/internet research written project concerning some aspect of the automobile’s effect on society

MA100 – Technical Mathematics

This course is designed to give an overview of the mathematical skills necessary to function in a technical environment while developing reasoning and problem solving skills. Topics taught in this course, in addition to the basic arithmetic skills dealing with whole numbers, fractions and decimals; include ratios and proportions, percent’s, standard and metric measurements and conversions, angle measurements, displacement levers, proportion of volume and measurement of tolerances. An emphasis is placed on technical and automotive applications like automotive business and statistics, repair orders, engine systems, electrical systems, drive train, chassis

AT209 – Automatic Transmissions II

This course provides classroom and laboratory hands-on activities concerning the inspection, construction, diagnosis and disassembly/assembly of automatic transmissions and transaxles. This builds on the material taught in AT208 Automatic Transmissions I and includes the construction, inspection and rebuilding of apply devices, planetary gear sets, oil pumps, valve bodies and one-way clutches. Students will become familiar with the tools and techniques necessary to properly maintain, diagnose, service and repair automatic transmissions. Students are exposed to a variety of transmission types to overhaul. The laboratory component of the course includes various activities