CR102 – Structural Analysis & Repair

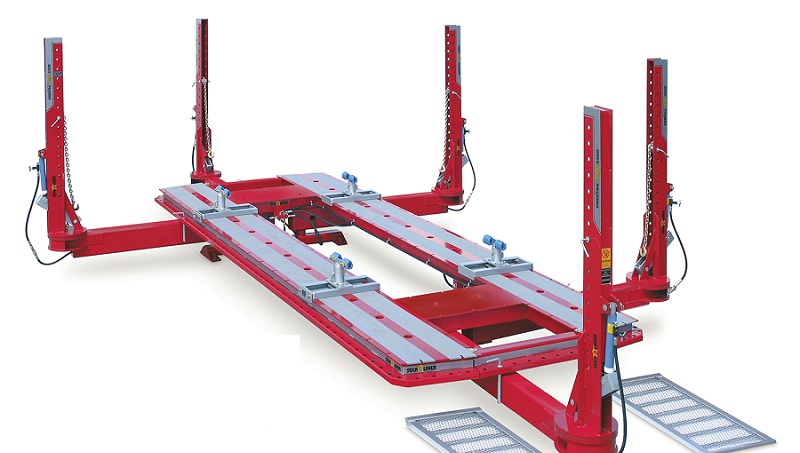

This class will focus on repairing structural damage to vehicles with frame type chassis. Students will learn how to straighten or replace damaged frame components using a frame machine. Students will also learn fixed glass replacement using manufacturers’ procedures. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the straightening and aligning techniques utilized in the repair of body-on frame vehicles will be assigned and is an integral component of

CR100 – Welding & Cutting

Students will learn welding techniques using MIG and arc welders and how to safely use oxy-acetylene. Students will learn how to identify the proper weld to use in different situations and how to join the different types of metal. Students will also learn the various cutting techniques. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the welding methods common to the collision repair industry will be assigned and is

CR103 – Unibody Analysis & Repair

This course combines lecture and laboratory hands-on activities, focusing on the fundamentals of unibody type chassis damage and repaired. Students will learn to properly measure, straighten and align body panels while using the frame machine and to locate hidden damages. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the straightening methods utilized to correct impact damage on unibody vehicles will be assigned and is an integral component of this

CR104 – Non-Structural: Preparation & Plastics

In this course students are provided classroom and laboratory hands-on activities concerning the preparation of body panels for repair. This will include the removal of trim and molding and protecting non-damaged panels. Repairs of rubber panels and bumpers will be demonstrated and students will learn how to repair movable glass. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the preparation of body panels for repair and refinishing will be

CR105 – Non-Structural: Panel Analysis & Repair

In this course students are provided classroom and laboratory hands-on activities concerning the removal, repair, replacement and adjustment of outer body panels. This will include the repair and alignment of doors, tailgates, trunk lids, hoods and fenders. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the repair, replacement and/or adjustment of removable outer body panels will be assigned and is an integral component of this course.

CR110 – Introduction to Refinishing

This course provides classroom and laboratory hands-on activities where the student is taught the proper procedures for using automotive refinishing equipment and the materials used in surface preparation and finish application. Emphasis is placed on personal safety, refinishing equipment and materials, surface preparation, masking, application techniques and other related topics. Additional topics discussed include the precautions which are necessary to safely handle finishing materials in accordance with federal, state and local requirements. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education

AT215 – Climate Control

This course provides classroom and laboratory hands-on activities concerning the theory and operation of heating and air conditioning systems. Students will learn about heat transfer, temperature/pressure relationships and control systems. Heating, air conditioning and passenger comfort will be looked at using multi-zone automatic climate control trainers. Students are taught to use refrigerant recovery and recharging equipment on laboratory vehicles which provides practical experience while reinforcing safety and environmental considerations. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A

AT202 – Advanced Electrical Systems

This is a comprehensive lecture and laboratory class which builds on the two previous electrical/ electronic courses. Emphasis is placed on the theory, operation, component identification and repair of audio and entertainment systems, power accessories such as power windows and locks, keyless entry, anti-theft systems and cruise control systems. Additional topics included in this course are the theory, operation and repair of various supplemental restraint systems. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written

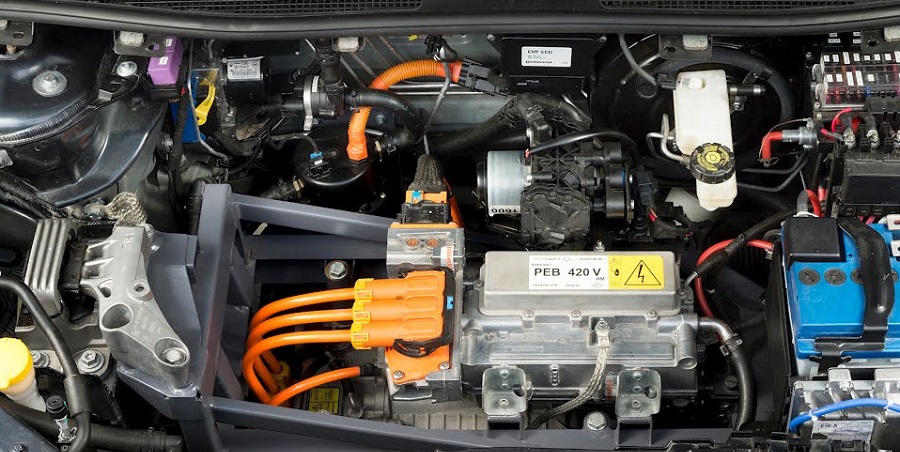

AT112 – Engine Electronics

This lecture/laboratory course utilizes the students’ prior understanding of electrical/electronic principles to better comprehend the complex electronically controlled systems used to monitor engine operation and emission compliance. Additionally students will study the theory of operation, design and problem diagnosis of modern ignition systems. Computerized engine controls, sensors and actuators and engine management systems will be discussed and diagnosed using the most sophisticated training aids in the industry. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research

AT110 – Electrical/Electronic Systems

This course provides classroom and laboratory hands-on activities where students building on material learned in AT108 Automotive Electrical Foundations use wiring diagrams to examine headlight, taillight, stoplight and turn/hazard light for operation and repair. Students are taught to use advanced diagnostic techniques to diagnose and repair electrical circuits associated with instrumentation, horn systems and wiper/washer systems. Students will learn on modern training aids using factory service procedures. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research