CR102 – Structural Analysis & Repair

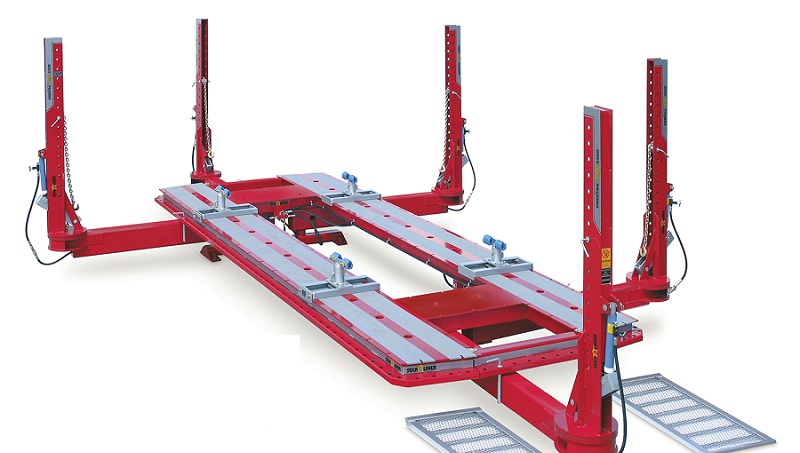

This class will focus on repairing structural damage to vehicles with frame type chassis. Students will learn how to straighten or replace damaged frame components using a frame machine. Students will also learn fixed glass replacement using manufacturers’ procedures. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the straightening and aligning techniques utilized in the repair of body-on frame vehicles will be assigned and is an integral component of

CR100 – Welding & Cutting

Students will learn welding techniques using MIG and arc welders and how to safely use oxy-acetylene. Students will learn how to identify the proper weld to use in different situations and how to join the different types of metal. Students will also learn the various cutting techniques. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the welding methods common to the collision repair industry will be assigned and is

CR103 – Unibody Analysis & Repair

This course combines lecture and laboratory hands-on activities, focusing on the fundamentals of unibody type chassis damage and repaired. Students will learn to properly measure, straighten and align body panels while using the frame machine and to locate hidden damages. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the straightening methods utilized to correct impact damage on unibody vehicles will be assigned and is an integral component of this

CR104 – Non-Structural: Preparation & Plastics

In this course students are provided classroom and laboratory hands-on activities concerning the preparation of body panels for repair. This will include the removal of trim and molding and protecting non-damaged panels. Repairs of rubber panels and bumpers will be demonstrated and students will learn how to repair movable glass. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the preparation of body panels for repair and refinishing will be

CR105 – Non-Structural: Panel Analysis & Repair

In this course students are provided classroom and laboratory hands-on activities concerning the removal, repair, replacement and adjustment of outer body panels. This will include the repair and alignment of doors, tailgates, trunk lids, hoods and fenders. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of the repair, replacement and/or adjustment of removable outer body panels will be assigned and is an integral component of this course.

CR110 – Introduction to Refinishing

This course provides classroom and laboratory hands-on activities where the student is taught the proper procedures for using automotive refinishing equipment and the materials used in surface preparation and finish application. Emphasis is placed on personal safety, refinishing equipment and materials, surface preparation, masking, application techniques and other related topics. Additional topics discussed include the precautions which are necessary to safely handle finishing materials in accordance with federal, state and local requirements. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education

TD210 Diesel Engine Accessories

This lecture/laboratory course focuses on the diesel engine accessories that aid in the enhancement of engine power, performance and lower diesel emissions. Topics discussed include air induction and exhaust systems, turbochargers, superchargers and engine braking systems. A thorough discussion of diesel engine system preventive maintenance and inspection practices are also included. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project concerning some aspect of a diesel engine’s air induction system, exhaust system, turbocharger, supercharger

EG102 – Technical Communications

This course continues the advancement of reading and writing in the context of the technical environment in which most students will work after achieving their degrees. Students will read and write technical reports, memos, personnel commentary and other documents of value in automotive work. Students will continue to advance their skills in research-based writing and will be required to submit a research-based report.

TD204 – Advanced Heavy Duty Undercarriage

This course combines lecture and laboratory hands-on activities, focusing on the theory of operation, construction, diagnosis and repair of heavy duty clutch assemblies, manual transmissions, drive lines and final drive assemblies. The laboratory component of the course includes the practical aspects of maintenance, troubleshooting and overhaul procedures used in heavy duty power train components. Chassis preventive maintenance and inspection (PMI) will be covered in detail. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF). A library/internet research written project

TD202 – Diesel Fuel Systems

This lecture/laboratory course begins with the discussion diesel engine fuel composition from crude oil to the distillation and compounding of fuels in accordance with American Petroleum Institute’s standards. Fuel delivery systems are discussed in detail including fuel tanks, pumps, fuel lines and filtration devices. The various mechanical and electronic fuel injection systems used on diesel engines are discussed in great detail with an emphasis engine performance and diesel emission requirements. The laboratory component of the course includes various activities that follow the guidelines of the National Technicians Education Foundation (NATEF).